- Machine Instruction:

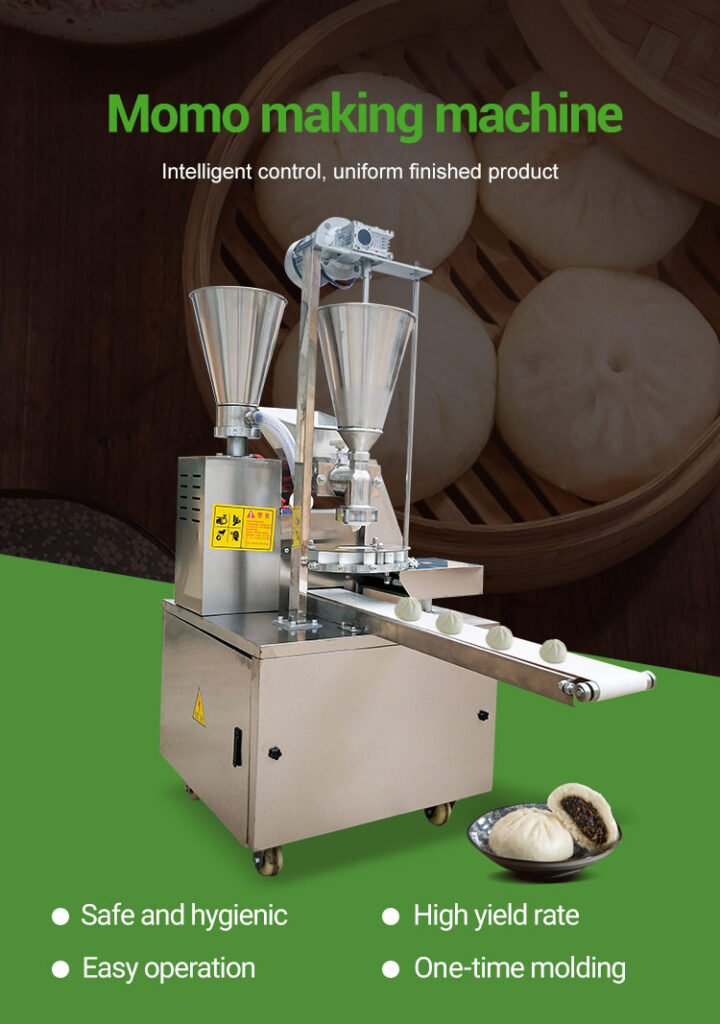

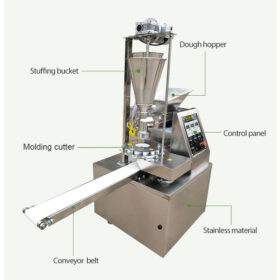

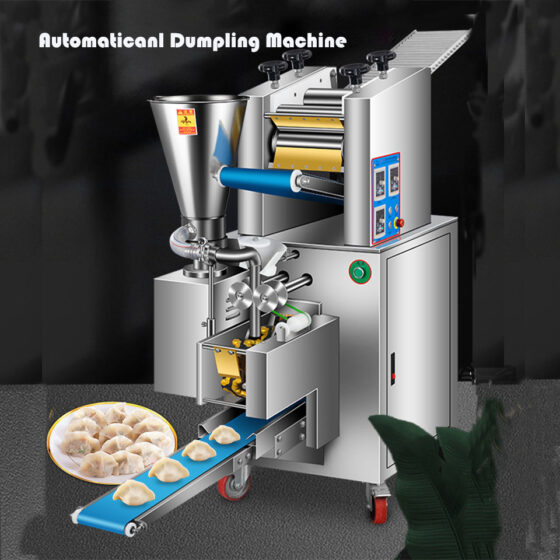

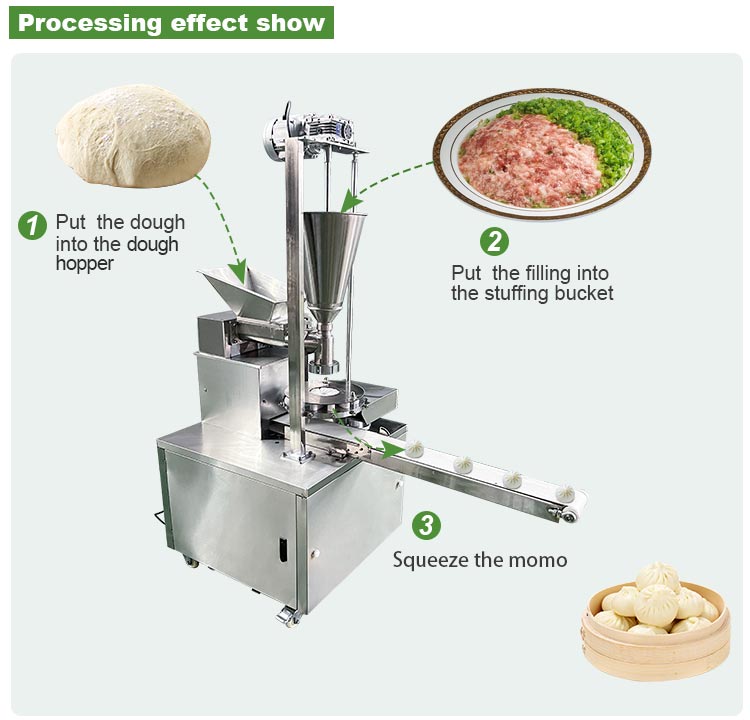

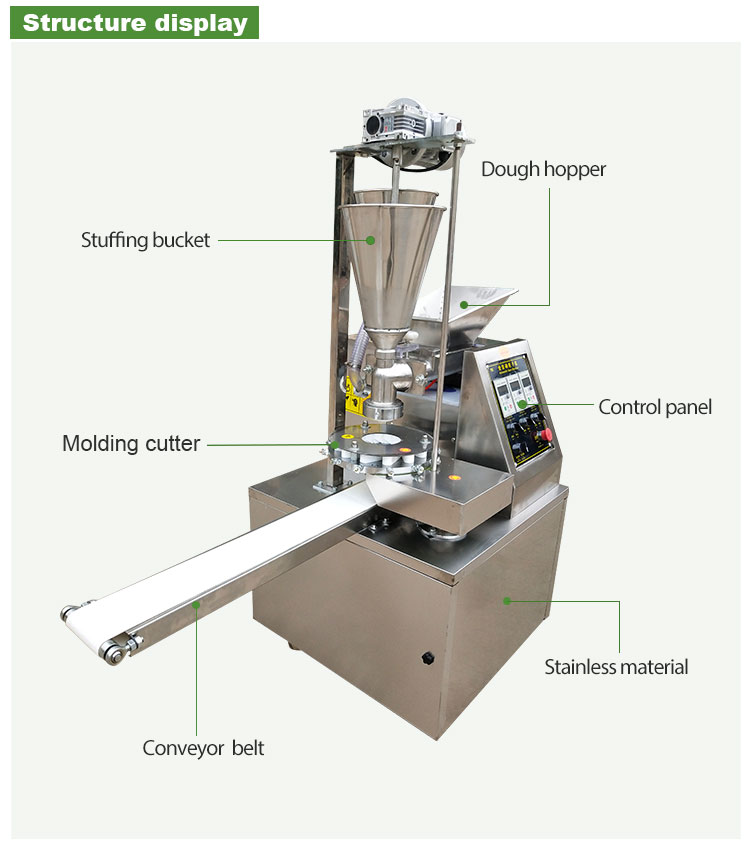

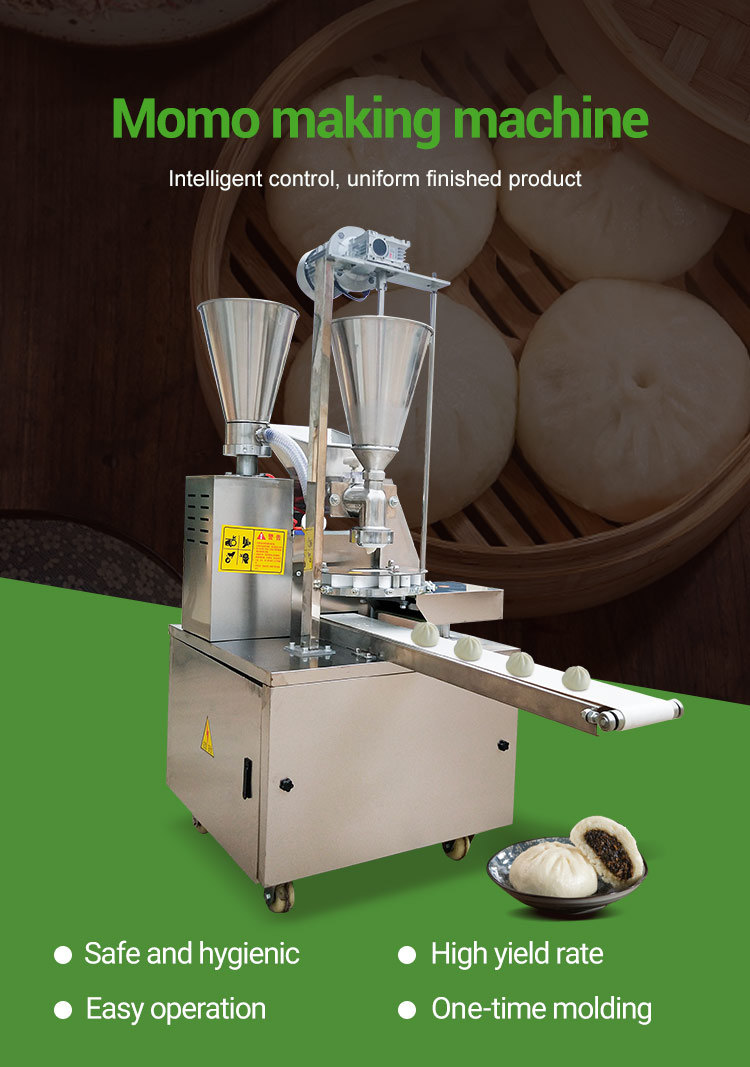

The bun machine is a food machine that puts the fermented dough and mixed fillings into the machine to process and make buns. Additional equipment can be configured

as needed: dough mixer, mixer, dough press, meat grinder, vegetable cutter, dicing machine, shredder, vegetable stuffing machine, stuffing mixer and so on.

2. how to maintenance

1). The machine should be cleaned in time after each used, as things that come into sticky food must be kept clean.

2). When disassembling and assembling the noodle and stuffing feeding mechanism and blades, it is strictly forbidden to use hard objects to smash, hit, pry and other bad operations.

3). Clean the blade and put it back. Please pay attention to the placement.

4). Add a little cooking oil or grease between the blades before starting the machine, and also inject an appropriate amount of cooking oil into the transmission parts.

5). Apply vegetable grease to the cam groove once per shift.

6). Each bearing should be disassembled and cleaned every six months.

7). Please follow the routine maintenance of mechanical and electrical products for the reduction motor.

3. about operating

1). Open the mold plate cover and add a small amount of lubricating oil or grease between the blades.

2). After turning on the power (must be protected by grounding), check the forward and reverse rotation, turn off all switches and let the machine run dry, and check whether all parts are normal.

3). When trying to make, first turn off the forming switch, then turn off the adjustment noodle pump switch, put the kneaded dough into the dough bucket until the machine makes hollow buns, then adjust the filling button to make buns according to the required proportion. amount, turn off the facial pump switch.

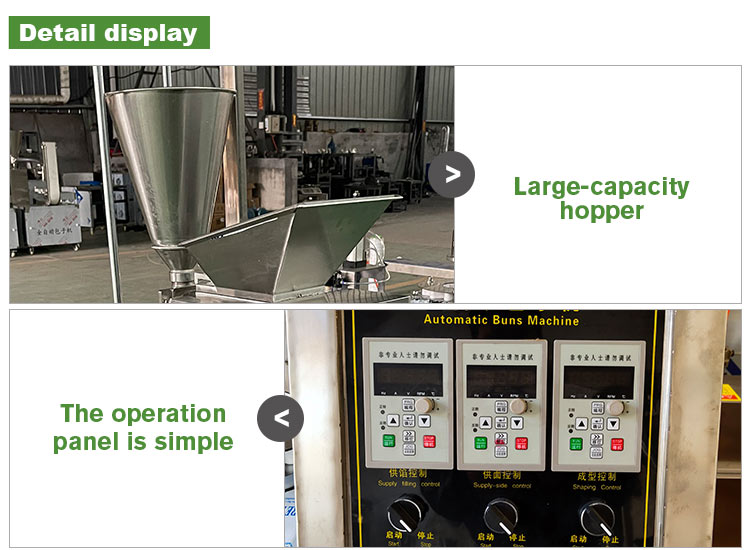

4). Turn off the stuffing pump switch, put the stuffing into the stuffing hopper, and let the stuffing come out of the machine head. Only when the stuffing fills the stuffing pump can the supply surface be turned off.

5). When the stuffed noodle column is formed by the mold plate and becomes a complete bun, adjust it (stuffing adjustment) to make the bun reach the required size and ratio of skin to filling.

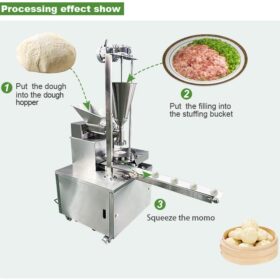

The steamed bun machine is easy to operate, can make steamed buns of various shapes, and can be put on the market relatively quickly. A brief introduction to the operation of the bun machine: Put the mixed dough into the dough hopper of the bun machine – Put the mixed stuffing into the stuffing hopper of the bun machine – Start the main power supply of the bun machine – Turn off the forming switch of the bun machine – Turn off the buns Machine noodle delivery switch – turn off the stuffing delivery switch of the bun machine – take out qualified buns from the conveyor belt.

CaiGuan Machinery

CaiGuan Machinery